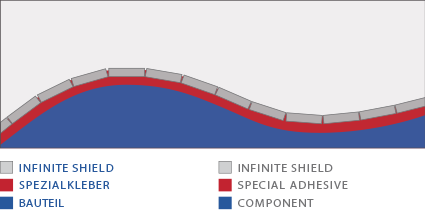

INFINITE SHIELD wear protection consists of ceramic elements. The small parts offer many advantages due to their shape and size. Due to the small size of individual elements and their optimized shape, the contour to be protected can be exactly followed. Thereby the system components are calculated for the optimal use of the hexagons, so that the functionality of the components will still be 100%.

INFINITE SHIELD

• consists of hexagonal or rectangular ceramic elements

• optimal contour adjustment to the component in need of protection

• extreme hardness, up to 2500 HV, therefore absolutely resistant to abrasion

• securely bonded up to 150°C, mechanically fixed above 150°C

• permanent bonding by high performance adhesive

• applied without any gaps

• used in new plants & for operative plants

INFINITE SHIELD LIGHT

• a competitive alternative to the high-end product INFINITE SHIELD

• high hardness, up to 1500 HV

The ceramic elements are stuck directly by special glue that is adjusted to the area parameters. The direct adhesion without an interlayer enables an optimum connection between the construction element and the ceramic elements.

• optimal contour adjustment

• constant adhesive layer with INFINITE SHIELD

• no gaps between the elements